Material Testing for laboratory

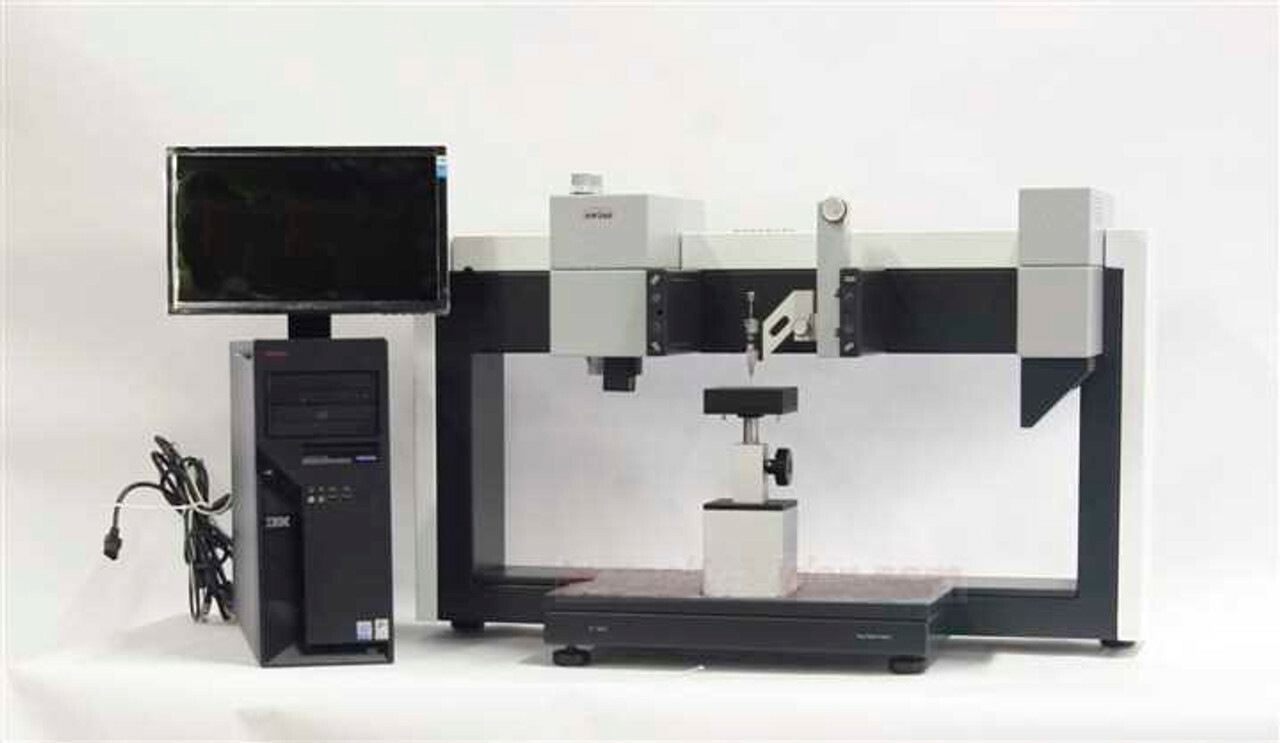

Lab physical material testing machines

A material testing laboratory is a specialized facility equipped with advanced instruments and tools used to analyze and evaluate the properties and characteristics of different materials. These laboratories play a crucial role in industries such as manufacturing, construction, automotive, aerospace, and research and development. The primary objective of a material testing laboratory is to ensure the quality, safety, and reliability of materials used in various applications.

In a material testing laboratory, highly trained technicians and engineers conduct a wide range of tests to assess properties such as strength, durability, elasticity, thermal conductivity, electrical conductivity, corrosion resistance, and more. These tests may involve mechanical testing, chemical analysis, thermal analysis, and microscopy techniques. The laboratory utilizes specialized equipment, including universal testing machines, spectrometers, calorimeters, hardness testers, and electron microscopes, to perform precise and accurate measurements.

Material testing laboratories are vital for quality control, product development, and research purposes. They help manufacturers ensure that their materials meet industry standards and regulatory requirements, ensuring the safety and performance of their products. Moreover, these laboratories contribute to advancements in material science by providing valuable data and insights that aid in the development of new materials and improvement of existing ones. By employing rigorous testing methodologies and state-of-the-art equipment, material testing laboratories play a pivotal role in enhancing product quality, innovation, and overall industry standards.