Essential Equipment Every Material Testing Lab Should Have

13th Jan 2025

Material testing plays a vital role across various industries, including research, manufacturing, and construction. Equipped with the right tools, laboratories can analyze the composition of materials and ensure compliance with industry standards. Reliable and precise testing is critical for product safety and quality assurance, while the absence of proper testing tools can lead to material failures and significant risks.

1. Universal Testing Machine (UTM)

The Universal Testing Machine is indispensable for evaluating material properties. It measures tensile, compressive, and bending strength by applying force and assessing the stress-strain relationship. UTMs are versatile, testing materials like metals, plastics, and alloys. This equipment is crucial for industries such as construction, aerospace, and automotive, ensuring materials meet strength and performance criteria under various forces.

2. Hardness Testing Machine

A hardness testing machine determines a material’s resistance to deformation or indentation. Methods like Rockwell, Brinell, and Vickers hardness tests provide valuable insights into durability, wear resistance, and strength. This tool is essential for evaluating materials used in machinery, tools, and construction, helping to ensure their suitability for specific applications.

3. Impact Testing Equipment

Impact testing equipment evaluates how materials withstand sudden forces, offering insights into toughness and impact resistance. The Charpy and Izod tests are commonly used, measuring energy absorption during impact. This equipment is vital for industries like construction and automotive, where materials frequently encounter dynamic forces, ensuring product safety and reliability.

4. Material Microscope

Material microscopes allow detailed examination of microstructures, revealing flaws, grain sizes, and surface characteristics invisible to the naked eye. Optical and Scanning Electron Microscopes (SEM) provide high-resolution imaging, aiding in failure analysis, quality inspection, and material characterization. This tool is crucial for improving material performance and adhering to stringent standards.

5. Thermal Analysis Instruments

Thermal analysis instruments evaluate how materials respond to temperature changes, measuring properties such as heat resistance and thermal expansion. Techniques like Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) offer insights into heat flow and mass changes under varying temperatures. These tools guide material selection for temperature-sensitive applications like engines and industrial equipment.

6. X-Ray Diffraction (XRD) Machine

X-Ray Diffraction is essential for identifying crystalline structures and phases at the atomic level. XRD provides detailed information about material composition and structure, aiding industries such as mining, aerospace, and electronics. It supports the development of innovative materials and enhances the performance of existing ones.

7. Creep Testing Machine

Creep testing machines assess a material’s deformation under constant stress over time, particularly at elevated temperatures. This is critical for evaluating materials used in high pressure or high temperature environments like power plants and engines. The data obtained helps predict material performance and longevity in demanding conditions.

8. Moisture Analyzer

Moisture analyzers measure the water content in materials, which can significantly impact properties such as weight, strength, and durability. These devices, often employing heat to remove moisture, are vital in industries like construction, food, and pharmaceuticals, ensuring quality and compliance with moisture content standards.

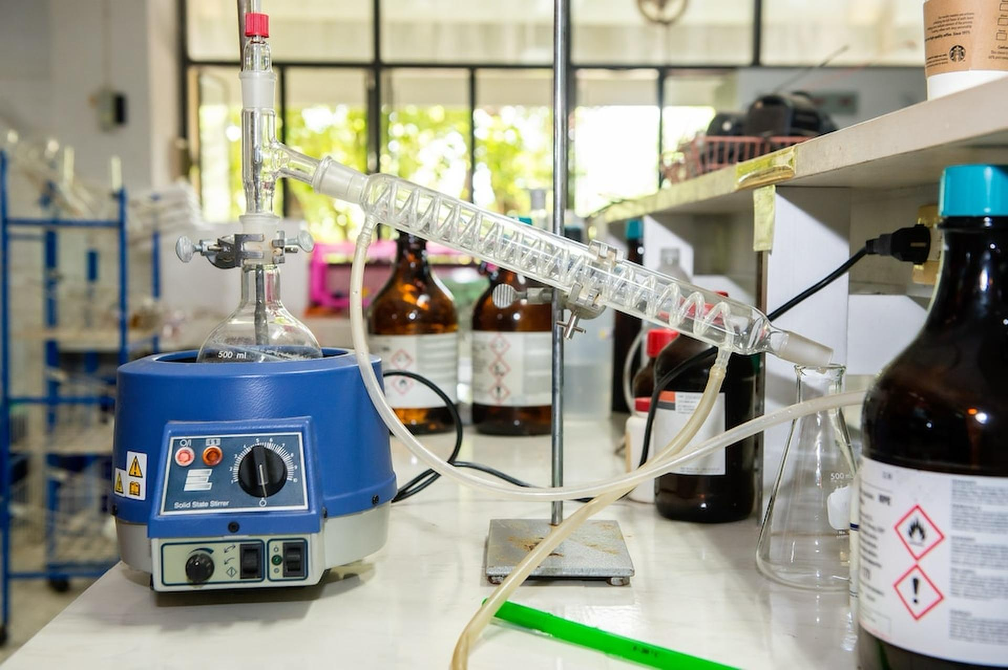

9. Spectrometer

Spectrometers analyze the chemical and mineral composition of materials by measuring emitted or absorbed light. Popular types include X-ray Fluorescence (XRF) and Optical Emission Spectrometers (OES). These tools are essential for verifying material composition in fields such as electronics, aerospace, and automotive, ensuring adherence to quality and chemical standards.

Conclusion

The right testing equipment is essential for ensuring material safety, quality, and performance across industries. From spectrometers to Universal Testing Machines, each tool plays a key role in comprehensive material evaluation. For over 40 years, HiTechTrader has been a trusted leader in laboratory instruments, providing reliable, sustainable solutions with unmatched quality and expertise. HiTechTrader empowers engineers and manufacturers to make informed decisions, choosing materials for their reliability, cost-effectiveness, and performance.