96-Well Plates and Homogenizers

22nd Jul 2025

Using 96-Well Plates and Homogenizers: A Practical Guide

Why Sample Homogenization Matters

Accurate results and fast operations are essential elements that guide research and production operations across laboratories and pharmaceutical manufacturing facilities. The essential laboratory practice of sample homogenization guarantees consistent outcomes with high precision. Homogeneous sample preparation techniques are essential for processing biological tissues before DNA extraction and plant materials for metabolomics studies.

The pairing of 96-well plates with homogenizers has revolutionized laboratory procedures because they facilitate large-scale simultaneous sample preparation. People who use this equipment regularly ask multiple questions about achieving optimal efficiency despite their widespread application. The guide offers practical step-by-step instructions to help your laboratory enhance consistency and decrease errors.

Equipment Overview

The first step before starting procedures requires understanding the equipment.

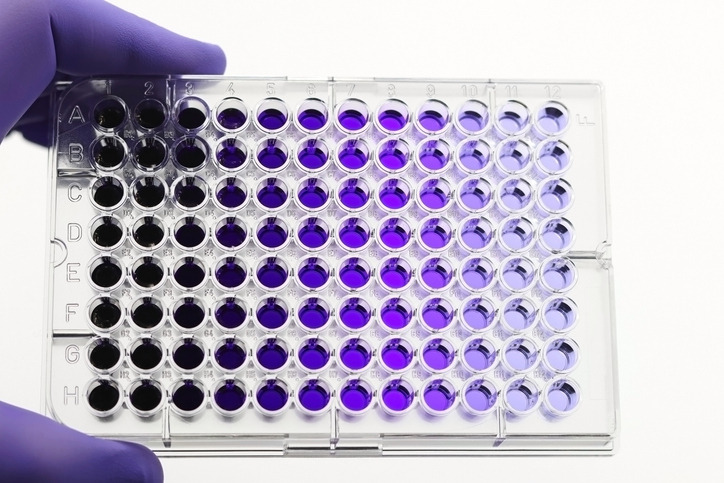

- A 96-well plate features an 8x12 arrangement of small-volume wells that operate in parallel fashion for laboratory applications.

- A homogenizer performs two operations by breaking materials while mixing them to generate a homogeneous solution.

A 96-well plate homogenizer enables rapid uniform processing of samples throughout every well. These homogenizers utilize three primary operational methods to function.

- Bead milling – small beads vibrate rapidly to disrupt cells or tissues.

- Ultrasonic energy – sound waves create cavitation bubbles that break apart materials.

- Mechanical agitation – rapid motion or vibration mixes contents.

These systems enable consistent processing of up to 96 samples at once, saving time and improving reproducibility.

Step-by-Step Protocol

Step 1: Add Sample and Beads

Your sample should be dispensed into each individual well of the 96-well plate.

Each well requires an equal amount of beads to maintain uniform homogenization.

Step 2: Add Buffer or Solvent (if required)

The appropriate buffer or solvent must be added for successful cell lysis or extraction processes.

The same volume should be used for each sample throughout the shaking process to keep everything balanced.

Step 3: Seal the Plate

Use a sealing mat or adhesive film compatible with homogenization.

The plate requires a tight seal to protect it from leaks and cross-contamination.

Step 4: Load the Plate into the Homogenizer

Insert the sealed plate into the homogenizer.

Follow manufacturer instructions to lock it securely.

Step 5: Set Parameters and Start

Set the speed and duration parameters according to your sample requirements while selecting the appropriate settings.

Typical run times range from 30 seconds to 5 minutes.

Step 6: Post-Homogenization Handling

After the processing procedure you need to handle the plate with care.

If necessary, use brief centrifugation to collect material that settles at the bottom of each well.

The samples are now prepared for analysis or storage.

Troubleshooting & Best Practices

Even with proper equipment, issues can arise. Here’s how to avoid common problems:

1. Use Compatible Consumables

Only use homogenizer-approved plates together with approved seals and beads.

Reusing consumables leads to potential warping and degradation of the materials.

2. Keep Volumes Consistent

Homogenization uniformity suffers when the volume measurements are inconsistent.

The use of multi-channel pipettes together with liquid-handling systems provides precise measurements.

3. Maintain and Calibrate Equipment

Check moving parts for any signs of damage during regular maintenance operations.

A maintenance and calibration log system should be established.

4. Ensure Proper Sealing

The sealing process needs to be proper to avoid both leaks and contamination.

Test your sealing method before running critical samples.

5. Control Temperature

Heat-sensitive materials become degraded because of the homogenization process.

The addition of cold blocks or pre-cooled plate plates helps to reduce heat accumulation.

Boosting Efficiency with Smart Sample Prep

Learning to use 96-well plates with homogenizers enhances laboratory operational efficiency. With appropriate tools along with established practices and protocol guidelines your team can process extensive sample sets efficiently with reliability.

Standardized homogenization workflows implemented in research labs as well as biotech firms and academic institutions boost productivity levels while producing reproducible results.