Types of Homogenization Methods: A Complete Guide

27th Aug 2025

Homogenization plays a critical role across scientific research, pharmaceuticals, food processing, and industrial manufacturing. By breaking particles down and distributing them evenly within a sample, homogenization ensures consistency, accuracy, and reliability. From tissue preparation in life sciences to chemical blending in industry, choosing the right homogenization technique can make or break your results.

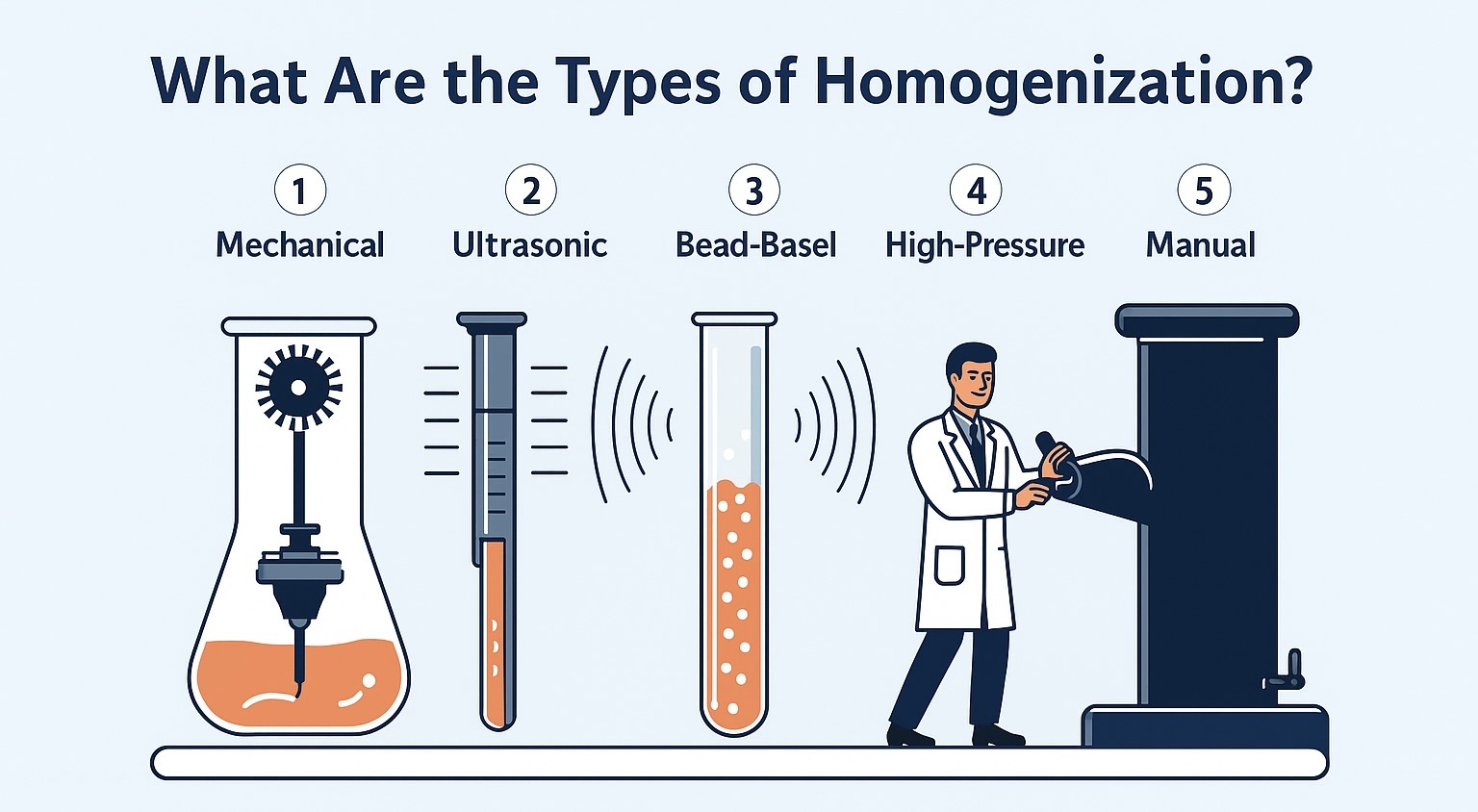

So, what types of homogenization methods are available today? The best option depends on your sample type, application, and scale of operation. Below, we’ll explore the five most common homogenization methods: mechanical, ultrasonic, bead-based, high-pressure, and manual homogenizers.

1. Mechanical Homogenization

Mechanical homogenizers are widely used in laboratories and industrial settings. They rely on blades or probes that generate strong shear forces to break apart and mix samples.

Rotor–Stator Homogenizers

These devices use a fast-spinning rotor inside a stationary stator. The narrow gap between them generates shear and turbulence, efficiently breaking particles and dispersing them.

-

Applications: Emulsions, cell lysis, tissue homogenization

-

Industries: Biotech, pharmaceuticals, food science

High-Shear Mixers

A larger-scale alternative, these mixers are designed for industrial processes requiring high throughput.

-

Advantages: Effective for viscous materials, scalable for mass production

-

Limitations: Heat generation may damage sensitive samples; less effective on fibrous tissues

Bottom Line: Mechanical homogenizers are versatile and scalable—ideal for labs and industries that need flexibility.

2. Ultrasonic Homogenization

Ultrasonic homogenizers use high-frequency sound waves to generate microscopic bubbles in liquids. When these bubbles collapse, they release shockwaves that disrupt cells and reduce particle size.

How It Works: A probe emits sound waves into the sample, causing rapid pressure fluctuations that form and collapse bubbles, releasing powerful localized energy.

-

Applications: DNA/RNA extraction, nanoparticle dispersion, liposome preparation, degassing liquids

-

Used In: Biotech, pharmaceutical, chemical, and environmental labs

-

Advantages: Precise, reproducible results; minimal mechanical friction; effective on small volumes

-

Limitations: Generates heat and noise; not suited for very large or viscous samples

Best For: Small-scale, delicate applications requiring precision and repeatability.

3. Bead-Based Homogenization

Also known as bead beating or bead milling, this method uses rapid bead collisions to mechanically disrupt samples.

How It Works: Samples are placed in sealed tubes with glass, ceramic, or metal beads. When shaken at high speed, the beads impact and grind the sample.

-

Applications: Breaking tough cell walls (plants, yeast, fungi), microbiome analysis, protein and DNA/RNA extraction

-

Used In: Molecular biology, clinical labs, agricultural and food research

-

Advantages: Effective for hard-to-lyse samples; high-throughput; minimizes contamination with sealed tubes

-

Limitations: Limited to small volumes; beads wear out over time

Best For: Tough, fibrous samples and high-throughput workflows.

4. High-Pressure Homogenization

This industrial-scale method forces liquids through a narrow valve at extremely high pressures—sometimes up to 30,000 psi. The sudden pressure drop and intense shear forces reduce particles to nanoscale sizes.

How It Works: A powerful pump drives the sample through a tight valve, where pressure, shear, and cavitation break down particles.

-

Applications: Pharmaceutical nanoemulsions, liposome creation, dairy processing, cosmetic and chemical formulations

-

Used In: Pharma manufacturing, food production, cosmetics, chemical plants

-

Advantages: Produces stable, uniform mixtures; easily scalable; reliable for large volumes

-

Limitations: High equipment cost; heat generation requires cooling for sensitive materials

Best For: Large-scale, high-precision applications requiring stable nanoscale dispersions.

5. Manual Homogenization

Manual homogenizers are simple, low-cost tools for small-scale or specialized applications. They require no electricity and are operated by hand.

Dounce & Potter-Elvehjem Homogenizers

These consist of a glass tube and pestle. By pressing and twisting, researchers can gently disrupt soft samples without damaging delicate structures.

-

Applications: Organelle isolation (e.g., mitochondria), soft tissue preparation, small-scale experiments

-

Used In: University research, teaching labs, studies requiring gentle handling

-

Advantages: Affordable, quiet, electricity-free, gentle on fragile samples

-

Limitations: Labor-intensive, limited sample capacity, user-dependent results

Best For: Gentle, low-cost, small-scale research applications.

Conclusion: Choosing the Right Homogenization Method

There’s no universal answer to which homogenization technique is best—it depends on your sample type, research goals, and production scale.

-

Mechanical: Best for versatility and scalability

-

Ultrasonic: Best for precision in small volumes

-

Bead-Based: Best for hard-to-break samples and high-throughput work

-

High-Pressure: Best for industrial, large-scale, nanoscale dispersions

-

Manual: Best for gentle, low-cost, small-batch research

Selecting the right method ensures reproducibility, efficiency, and the highest quality results for your lab or production line.