Choosing the Right Process Equipment Without the Guesswork

15th Nov 2024

For industrial professionals, reliable process equipment is a must. Whether maintaining safe working conditions or optimizing processes, choosing the right tools can mean the difference between seamless operations and costly disruptions. With options ranging from budget-friendly imports to U.S.-made machinery, it's essential to understand what you’re getting. Let’s explore key considerations, industry stats, and top-notch solutions to help you make an informed choice.

Why Quality Is Non-Negotiable in Process Equipment

Precision and reliability are the backbone of safe and efficient industrial processes. Low-quality heat exchangers, pressure transmitters, or other essential equipment can compromise accuracy, safety, and productivity.

Key reasons to prioritize quality:

- Consistent Performance: Precision tools ensure smooth operations and reduce downtime.

- Safety and Compliance: Equipment that meets strict standards minimizes risks and ensures compliance with regulations.

- Long-Term Value: Durable, high-quality machinery reduces repair and replacement costs over time.

While importing from countries like China offers cost advantages, the trade-offs often include inconsistent quality, subpar materials, and limited after-sales support.

The Case for U.S.-Manufactured Equipment

Choosing American-made process equipment offers clear advantages for professionals who prioritize quality and efficiency:

- High-Precision Standards: U.S. manufacturers excel in creating equipment that meets stringent performance benchmarks.

- Regulatory Compliance: American products adhere to strict safety and environmental standards, ensuring peace of mind.

- Reliable Support: Local sourcing simplifies maintenance, spare parts availability, and technical assistance.

- Faster Lead Times: Reduced logistics delays help you stay on schedule.

- Economic Benefits: Supporting domestic manufacturing bolsters the U.S. economy and drives innovation.

Investing in domestic equipment means fewer surprises and more consistent results, especially for critical industrial applications.

Balancing Cost and Quality

To understand the balance between cost and quality, consider these industry trends:

- S. Manufacturing Output: In 2021, the U.S. manufacturing sector was valued at $2.5 trillion, an 11.55% increase from 2020.

- Imports from China: In 2022, the U.S. imported $536.8 billion worth of goods from China, with machinery and mechanical appliances accounting for 46.4%.

Many industries weigh the cost savings of imports against the superior quality and compliance of U.S.-made equipment. Supply chain disruptions in recent years have also led some professionals to reassess their reliance on overseas suppliers.

Heat Exchangers Efficiency You Can Count On

Heat exchangers play a crucial role in temperature control across industries. Investing in a reliable model ensures consistent performance, energy efficiency, and long-term durability.

Take the AIC Plate Heat Exchanger Model A190, for example:

- Manages up to 40 gallons per minute.

- Features AISI 316 stainless steel plates for durability and corrosion resistance.

- 42 plates provide 95.9 square feet of heat transfer area.

Efficient heat exchangers help reduce operational costs by maximizing energy transfer and minimizing waste—a win-win for your bottom line and the environment.

Why Pressure Transmitters Matter

A dependable pressure transmitter is essential in industries where maintaining exact pressure levels is critical. The Rosemount 3051 Differential Pressure Transmitter is an excellent example of how advanced technology enhances precision and reliability.

Why invest in quality pressure transmitters?

- Ensure systems operate within safe and efficient parameters.

- Withstand harsh industrial conditions without compromising performance.

- Seamlessly fits into existing systems for effortless upgrades.

Reliable transmitters are not just a luxury—they're a necessity for ensuring process safety and efficiency.

The Hidden Risks of Inexpensive Imports

While imported equipment can save upfront costs, professionals must account for potential risks:

- Inconsistent Quality: Some imported products, especially from China, may not meet the precision standards needed for high-performance industries, as their manufacturing often focuses on mid-to-low-end products.

- Material Concerns: Cost-cutting measures in manufacturing sometimes result in inferior materials or components, leading to reduced durability and accuracy.

- Limited Support: Delays in maintenance, spare parts, or technical help can cause extended downtime and compromise accuracy.

- Regulatory Issues: Non-compliant equipment may need costly modifications to meet regulations, affecting performance and precision.

Mitigating these risks involves due diligence, from verifying supplier credentials to evaluating the total cost of ownership.

Balancing Cost, Quality, and Convenience

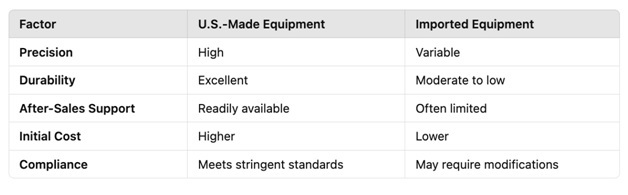

Choosing between U.S.-made and imported process equipment often depends on your priorities. Here’s a quick comparison:

For professionals who value reliability and safety, domestic equipment often proves more cost-effective in the long run.

Tips for Selecting the Right Equipment

When choosing heat exchangers, pressure transmitters, or other process tools, keep these tips in mind:

- Define the specific requirements of your operations.

- Opt for manufacturers known for quality and reliability.

- Factor in maintenance, energy efficiency, and long-term value.

- Ensure compliance with industry standards.

Reliable Solutions from HiTechTrader

At HiTechTrader, we understand the importance of reliable process equipment for industrial operations. That’s why we offer a carefully curated selection of high-quality tools, including:

- AIC Plate Heat Exchanger Model A190: Designed for efficiency and durability.

- Rosemount 3051 Pressure Transmitter: A precision solution for critical applications.

Whether you’re upgrading your facility or planning a new project, we’re here to help. Explore our inventory and find the equipment you need to keep your operations running smoothly.

Reach out today—we’re ready to support your success.