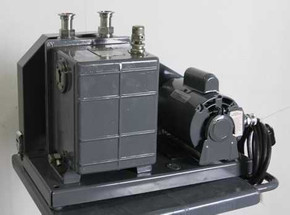

Seepex Progressive Cavity Pump

The Seepex Progressive Cavity Pump is a positive displacement pump designed to move fluids seamlessly, even when dealing with extreme viscosities, suspended solids, or shear-sensitive media. By employing a helical rotor inside a double-helix stator, the pump forms progressive cavities that gently transport fluids from suction to discharge with precision and minimal pulsation. Built for demanding industrial and laboratory applications, it ensures consistent, efficient, and reliable fluid transfer where controlled flow is essential.

At HiTechTrader, we offer refurbished Seepex Progressive Cavity Pumps that deliver the same dependable performance as new units, without the steep investment. Each pump is carefully restored, tested, and configured to meet the rigorous demands of modern process environments. With abrasion-resistant construction, Smart Conveying Technology (SCT) for simplified servicing, and the ability to handle pressures up to 48 bar and temperatures as high as 180 °C, these pumps provide outstanding value for wastewater treatment, chemical industries, food and beverage processing, and energy production. Their flexible installation options and gentle handling of sensitive materials make them a trusted, long-term solution for laboratories and large-scale facilities alike.

Purpose

The Seepex Progressive Cavity Pump is engineered for continuous, pulse-free fluid transfer with minimal shear. It is widely used in:

- Wastewater treatment and sludge handling

- Food and beverage production

- Chemical and petrochemical processing

- Oil, gas, and renewable energy industries

Vessel and Construction

- Capacity Range: 0.06 L/h to 500 m³/h (0.016 USGPH to 2200 USGPM)

- Pressure Capability: Up to 48 bar (720 psi), with higher-pressure versions available

- Temperature Range: -20 °C to +180 °C (0 °F to 360 °F)

- Suction Lift: Up to 9 meters (29.5 ft), including self-priming with gaseous liquids

- Installation Flexibility: Horizontal, vertical, or custom setups

- Build Quality: Abrasion-resistant, clog-preventive, and optimized for handling solids-laden fluids

Closure and Sealing

- Precision rotor-stator geometry ensures tight sealing

- Plug-in connections for leak-free operation and simple assembly

Operating Parameters

- Smart Conveying Technology (SCT):

- 1-stage (up to 4 bar) and 2-stage (up to 8 bar) versions

- Two-piece stator halves for wear compensation and fast maintenance

- Quick-release rotor design reduces service downtime

- Efficiency: Optimized energy consumption for lower operational costs

- Maintenance-Friendly: Plug-in joints, thru-bolt flanges, and service kits extend pump life

- Fluid Handling: Gentle conveyance preserves product quality with minimal shear

- Flexibility: Reversible flow direction for adaptable process control

Accessory Compatibility

- Customizable drives and motor configurations

- OEM and aftermarket service kits (rotors, stators, wear parts)

- Mounting accessories for diverse applications

- Adaptable for dosing, metering, and continuous pumping

Safe Operation Guidelines

- Always align and secure pump before operation

- Avoid dry running to protect stator and rotor integrity

- Verify torque and rotation direction during setup

- Regularly inspect stator wear and adjust SCT system accordingly

- Flush and clean pump after handling abrasive or corrosive media

- Operate only within rated temperature and pressure conditions

Applications

The Seepex Progressive Cavity Pump is commonly used for:

- Wastewater & sludge treatment

- Food & beverage transfer of delicate or shear-sensitive materials

- Chemical, oil & gas process control

- Biogas and anaerobic digestion

- Metering & dosing of abrasive, viscous, or aggressive fluids

Why Buy from HiTechTrader?

HiTechTrader provides refurbished Seepex Progressive Cavity Pumps that deliver proven performance and significant cost advantages. Each unit is:

- Fully tested, performance-verified, and ready for immediate integration

- Available at substantial savings compared to new equipment

- Supported with warranty and evaluation options for buyer confidence

- Backed by expert guidance for configuration, drive selection, and installation

With HiTechTrader's technical expertise and precision refurbishment, customers gain a durable, efficient, and service-friendly pumping solution designed to maximize uptime and extend operational life, making it the smart choice for industries where fluid handling reliability is non-negotiable.