Laboratory chillers and process chillers serve distinct purposes and are designed to meet different cooling requirements in various settings. Understanding the main differences between these two types of chillers is essential for selecting the appropriate cooling system for specific applications.

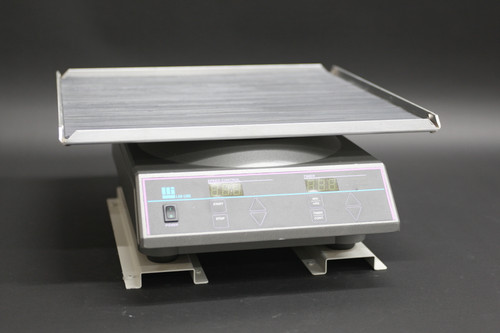

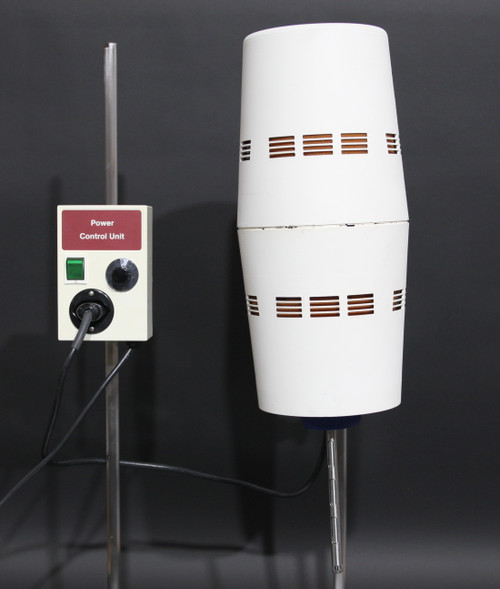

- Application and Capacity: The primary difference between a laboratory chiller and a process chiller lies in their application and capacity. Laboratory chillers are typically smaller, portable, and designed for cooling individual laboratory equipment, such as analytical instruments, spectrophotometers, or rotary evaporators. They are ideal for maintaining precise and stable temperatures required for sensitive experiments and research. On the other hand, process chillers are larger, industrial-grade cooling systems used in manufacturing processes and commercial applications. They are capable of handling higher cooling loads and cooling larger volumes of water or other heat transfer fluids, making them suitable for cooling multiple equipment or large-scale industrial processes. Thermo Neslab ThermoFlex 3500 Recirculating Chiller Air Cooled would be an example of a process chiller for industrial applications.

- Temperature Control: Another key difference is the level of temperature control provided by each type of chiller. Laboratory chillers are designed to offer precise temperature control, with the ability to maintain tight temperature ranges necessary for laboratory experiments. They often come with advanced temperature control features and high temperature stability. Process chillers, while still offering accurate temperature control, may have a broader temperature range as they cater to a wider range of industrial processes, which may not require the same level of precision as laboratory applications.

- Cooling Capacity and Efficiency: Process chillers are engineered to handle higher cooling capacities, making them more suitable for cooling multiple processes simultaneously or cooling large volumes of liquids or gases. Their cooling efficiency is optimized to provide continuous and reliable cooling in industrial environments. Laboratory chillers, while efficient in cooling specific laboratory equipment, may not be as suitable for handling high-capacity cooling loads found in industrial settings.

- Construction and Durability: Laboratory chillers are typically designed for lighter use and may have a more compact and portable design. They are commonly used in controlled laboratory environments, where the operating conditions are relatively stable. Process chillers, on the other hand, are built to withstand more demanding industrial conditions and may have a more robust construction to handle heavy-duty usage and harsh environments.

- Customization and Control Features: Process chillers often offer greater customization options to meet the specific needs of industrial applications. They can be tailored to suit various cooling requirements, such as low-temperature chilling or high-temperature process cooling. Additionally, process chillers may have advanced control features and remote monitoring capabilities to integrate with complex industrial processes and control systems. Laboratory chillers, while providing precise temperature control, may have fewer customization options and control features due to their focus on specific laboratory equipment cooling.

In summary, the main differences between a laboratory chiller and a process chiller lie in their application, cooling capacity, temperature control, cooling efficiency, construction, and customization options. While laboratory chillers are designed for precise cooling of laboratory equipment, process chillers are engineered for larger-scale cooling applications in industrial environments. Selecting the appropriate chiller depends on the specific cooling requirements of the application and the cooling capacity needed to ensure efficient and reliable cooling.